Knuckle Joint

The knuckle joint is a type of hinge used for connecting two pieces of wood, metal or other rigid objects. It consists of an upright and cross piece that can rotate on its own axis relative to the remaining piece, allowing it to pivot inwards and outwards without breaking free from either side.

The knuckle joint is a bony protuberance on the distal end of each finger that articulates with the metacarpals. It is also called the transverse ligament or lunate suture. The function of this joint in humans and other primates is to join, stabilize, and move flexor tendons attached to phalanx bones at their proximal ends.,

The “knuckle joint example” is a visual demonstration of how knuckle joints work. This is an easy way to understand the mechanics of this type of joint.

A knuckle joint is a kind of connection that connects two rods that are subjected to tensile stresses. The rods, on the other hand, may be able to withstand a compressive force provided the joint is directed.

For modifications or repairs, a knuckle joint may be easily detached.

It may be found in a cycle chain link, a tie rod junction for a roof truss, a valve rod joint with the eccentric rod, a pump rod joint, a tension link in a bridge construction, and a variety of lever and rod connections.

Joint of the Knuckles Construction:

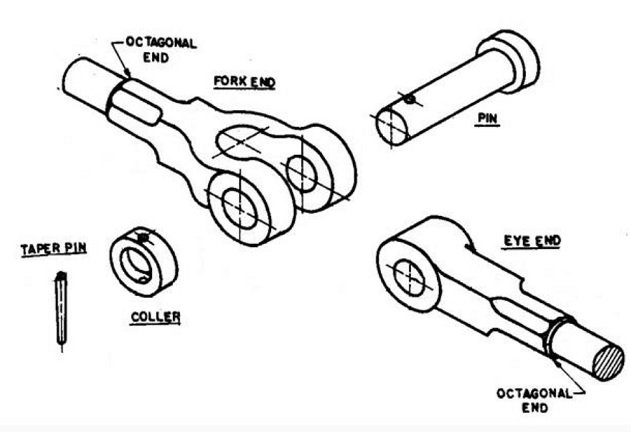

- One end of one of the rods is shaped into an eye in the knuckle joint (two views shown in Fig.) and the other end of the rod is created into a fork with an eye in each of the fork legs.

- The knuckle pin is attached with a collar and taper pin or a spilt pin and runs through both the eye and fork holes. A tiny stop, pin, peg, or snug may be used to keep the knuckle pin from turning in the fork.

- The sides of the fork and eye are machined, the hole is precisely drilled, and the pin is rotated to improve the connection quality. Steel or wrought iron may be used to make the joint.

knuckle joint components

Parts for Knuckle Joints:

The knuckle joint is made up of three primary parts:

- Eye,

- Fork and

- Figure 1 shows how to pin.

On one of the rods, the eye is produced, and on the other, the fork is formed. The eye is inserted into the fork, and the pin is threaded through the fork and eye. A split pin is used to keep this pin in its place. The rods’ ends are octagonal for a short distance for improved grip then square for a short distance before being forged into the eye and fork forms.

a schematic of the knuckle joint

a schematic of the knuckle joint

A Knuckle joint must be designed using empirical relationships.

Empirical relationships are used to determine the size of different sections of the knuckle joint, as shown below. It’s worth noting that all of the components should be made of the same material, such as mild steel or wrought iron.

When d is the rod’s diameter 1. Pin on the knuckles diameter d1=d 2. Eye outer diameter d2=2d 3. Knuckle pinhead or collar diameter d3=1.5d 4. Single eye rod thickness (t=1.25d) 5. t1=1.25d t1=1.25d t1=1.25d t1=1.25d t1=1.25d t2=1.25d Thickness of knuckle pinhead or collar

Knuckle joint design

Rod failure in tension

Tensile force may cause rod to fail under tension. Rod tensile strength, P = /4 x2 x

The diameter of the rod may be calculated using this equation.

Knuckle pin diameter in shearing

Because the pin is in double shear, its shearing strength is equal to 4 x 12 x

1=d 1=d 1=d 1=d 1=d 1=d 1=d 1=d 1=d 1=d 1

Empirical relationships may be used to fix the dimensions.

Pin diameter = 1 =d Diameter at the rim. 2 =2d of a single or double eye Knuckle pinhead and collar diameters = 3 = 1.5d Single eye thickness = t = 1.25d Fork thickness = 1 = 0.75d Collar pin thickness =t2 = 0.5d

Checking a single eye’s failure in tension = p/(d2-d1) x t

p/d1 x t = p/d1 x t = p/d1 x t = p/d1 x t = p/d1 x t

p/(d2-d1) x t = p/(d2-d1) x t = p/(d2-d1) x t = p/(d2-d1) x t = p/(d

Checking for double eye failure in tension = p/2(d2-d1) x t1

p/2d1 x t1 = p/2d1 x t1 = p/2d1 x t1 = p/2d1 x t1 = p/2d1 Checking for double eye failure in shear = p/2(d2-d1) x t1

The following are some of the benefits of a knuckle joint:

- It’s easy to design and make.

- Fewer components mean lower costs and more dependability.

- It’s easy to put together and take apart.

- Large tensile loads may be absorbed by the knuckle joint.

- It has a high level of mechanical stiffness.

- It’s simple to make and set up.

- The design is basic and straightforward.

Knuckle Joint Drawback:

- It is not designed to withstand significant compressive stresses.

- Allow just one plane of angular movement.

Knuckle joint applications include:

- The link in the cycle chain

- Roof truss tie rod joints

- eccentric rod pump rod joint valve rod junction

- In the structure of a bridge, there is a tension link.

- Various kinds of lever and rod connections.

- two-wheeler swing arm

- In multi-axle cars, the link rod of the leaf springs is connected.

- Connecting Rod, Piston, and Piston Pin

- Connections between the leaf spring and the chassis

What is the difference between a knuckle and a cotter joint?

| Sr. No. | Knuckle Joint | Cotter Joint is a kind of joint that is made from of |

|---|---|---|

| 1. | It can only withstand a tensile load. | Can withstand both tensile and compressive loads. |

| 2. | Allows for angular movement between the rods. | There is no room for angular movement. |

| 3. | Bearing failure has occurred. | Bearing failure is not a concern. |

| 4. | There was no taper or clearance offered. | There is a taper or a clearance offered. |

| 5. | Tie bars, bicycle chain links, and rail shifting mechanism joints are all examples of applications. | Application: cotter foundation bolt, pipe connection between two rods, piston rod connection with c/s head |

Answers to the questions:

1. Explain “knuckle pin failure in bending” using a simple graphic.

In practice, the knuckle pin is slack in forks to allow angular movement of one relative to the other, thus the pin is bent as well as sheared. By increasing the knuckle’s diameter.

A margin of strength is supplied to allow for the bending of the pin, with the diameter of the pin equal to the diameter of the rod (i.e., d1 = d).

If bending stress is taken into consideration, the load on the pin is considered to be equally distributed throughout the center part (i.e. the eye end) and varies uniformly along the forks, as illustrated in Fig. As a result, a load P/2 operates across a distance of t1 / 3 from the inner edge of the forks, and the bending moment is greatest at the pin’s center. The maximal bending moment is calculated as follows:

knuckle joint pin failure

knuckle joint pin failure

2. What are examples of the Knuckle Joint’s real-world applications?

- The suspension bridge’s link

- The reciprocating engine’s valve mechanism

- Chain for a bicycle

- Lever’s fulcrum

- Parts for tractor wheel alignment

- Arms made of robots

3. What kind of material is utilized to make the knuckle joint?

Steel and wrought iron are utilized for all sections of the knuckle joint, including the fork end, knuckle pin, taper pin, collar, and eye end.

4. What is the definition of a knuckle joint?

Knuckle joints are mechanical joints that are used in buildings to link two crossing cylindrical rods whose axes are in the same plane. Between the cylindrical rods, it allows for some angular movement (in their plane). It has been built specifically to resist tensile loads.

Knuckle Joint Components:

The following are the components of a typical knuckle joint:

Fork end

Eye end

Knuckle pin

Collar

Taper pin

Thorat, Sachin

Sachin is a Mechanical Engineering B-TECH graduate from a reputable Engineering institute. He is now employed as a designer in the sheet metal sector. He is also passionate in Product Design, Animation, and Project Design. He also enjoys writing articles about mechanical engineering and uses his original project ideas, design, models, and videos to inspire other mechanical engineering students.

Recent Articles

Hydraulic seals – Definition, Types, Diagram, Function, Failure, Application link to Plastic Material – Types, Properties, Applications

The “knuckle joint parts” is a device that allows for the user to open and close their hand with ease. The knuckle joint has been around since ancient times, but it has recently been re-invented.

{“@context”:”https://schema.org”,”@type”:”FAQPage”,”mainEntity”:[{“@type”:”Question”,”name”:”What is knuckle joint in hand?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”A: The knuckle joint is a very flexing hinge at the base of your fingers, running from top to bottom on each hand. Its so important that its been named twice–once as the articulating or pivotable knuckle and once as the metacarpal.”}},{“@type”:”Question”,”name”:”What type of joint is knuckle joint?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”A: A knuckle joint is a type of hinge joint that connects one bone to another. This allows for the protection and movement of the bones in your fingers, hand, wrist, elbow and shoulder.”}},{“@type”:”Question”,”name”:”Where is knuckle joint used?”,”acceptedAnswer”:{“@type”:”Answer”,”text”:”A: The knuckle joint is used in the fingers. It facilitates movement of the hand and allows for fine-tuned manipulation.”}}]}

Frequently Asked Questions

What is knuckle joint in hand?

A: The knuckle joint is a very flexing hinge at the base of your fingers, running from top to bottom on each hand. Its so important that its been named twice–once as the articulating or pivotable knuckle and once as the metacarpal.

What type of joint is knuckle joint?

A: A knuckle joint is a type of hinge joint that connects one bone to another. This allows for the protection and movement of the bones in your fingers, hand, wrist, elbow and shoulder.

Where is knuckle joint used?

A: The knuckle joint is used in the fingers. It facilitates movement of the hand and allows for fine-tuned manipulation.

Related Tags

- knuckle joint in automobile

- knuckle joint application

- knuckle joint design

- knuckle joint assembly

- in case of knuckle joint pin is likely to fail in

![[FIX] MySQL ERROR 1046 (3D000) No Database Selected · Tech Support Whale](https://tomtechblog.com/wp-content/uploads/2021/11/FIX-MySQL-ERROR-1046-3D000-No-Database-Selected-C2B7-Tech.png)