Understanding Tremie Hopper: An In-depth Analysis

The tremie hopper is a critical piece of equipment in the construction industry, specifically in the placement of concrete underwater. This method, known as the tremie method, allows for the controlled and efficient pouring of concrete into foundations, piles, and other underwater structures without contamination or segregation. This article delves into the components, functions, applications, and advancements of the tremie hopper, highlighting its significance in modern construction.

Components and Structure

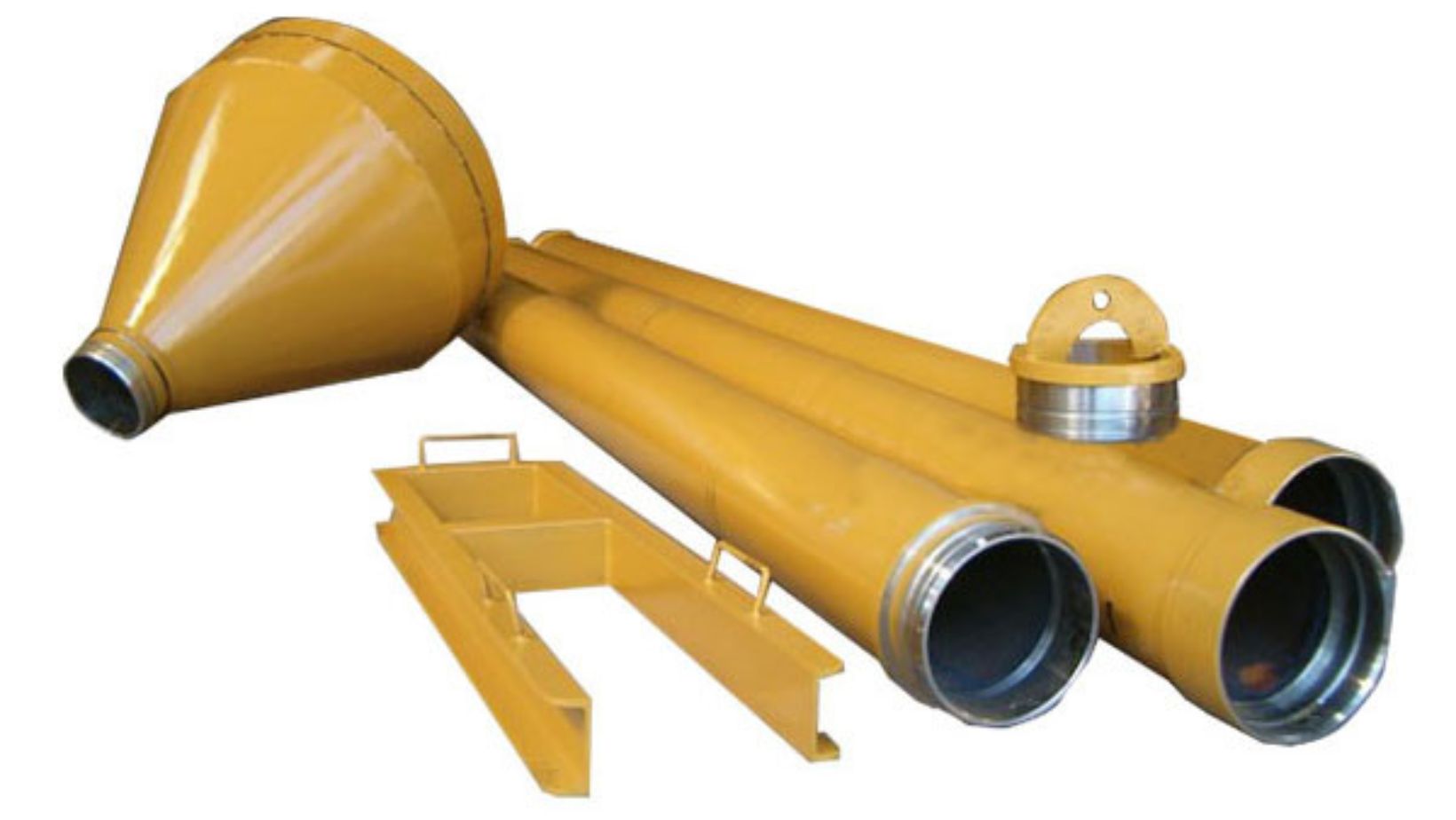

Hopper

The hopper is the main container or funnel through which concrete is introduced into the tremie system. It is typically designed with a wide top opening to facilitate easy pouring from concrete mixers or buckets. The hopper narrows towards the bottom, directing the concrete flow into the tremie pipe. This design ensures a consistent and controlled flow of concrete, which is crucial for maintaining the quality and integrity of the underwater pour.

Tremie Pipe

The tremie pipe is a long, cylindrical tube that extends from the bottom of the hopper to the placement site underwater. It is usually made of steel or durable plastic materials that can withstand the pressures and conditions of underwater construction. The pipe is sectional, allowing for adjustments in length to reach various depths. Its diameter can vary depending on the project’s requirements, but it generally ranges from 200 to 300 millimeters.

Valve or Plug

At the bottom of the tremie pipe, a valve or plug is installed to control the flow of concrete. This component is essential for starting and stopping the pour as needed. The valve or plug prevents water from entering the pipe during the initial stages of the pour, ensuring that the concrete remains uncontaminated. Once the pipe is submerged and positioned correctly, the valve is opened or the plug is removed to allow the concrete to flow.

Functioning of the Tremie Hopper System

Initial Setup

The tremie hopper system is set up by assembling the tremie pipe sections to the desired length and attaching them to the hopper. The pipe is then positioned vertically in the water, with its bottom end resting on the placement surface. The valve or plug is checked to ensure it is securely closed to prevent water ingress.

Concrete Pouring

Concrete is poured into the hopper from a mixer or bucket. As the concrete fills the hopper, it flows into the tremie pipe. The initial batch of concrete acts as a seal, preventing water from entering the pipe and mixing with the subsequent concrete batches. The controlled flow ensures that the concrete displaces the water at the placement site, creating a clean, uncontaminated pour.

Continuous Pour

The pouring process continues in a steady, continuous manner to maintain a constant pressure and flow within the tremie pipe. This consistency is crucial to avoid segregation and ensure a homogeneous mixture.

As the concrete is placed, the tremie pipe is gradually lifted to keep its bottom end submerged in the concrete, preventing water from entering and maintaining the integrity of the pour.

Applications of the Tremie Hopper

Underwater Foundations

One of the primary applications of the tremie hopper is in the construction of underwater foundations for bridges, piers, and offshore structures. These foundations require precise and uncontaminated concrete placement to ensure stability and durability. The tremie method allows for the controlled and efficient pouring of concrete, which is critical for these structures’ long-term performance.

Piling and Caissons

Piling and caisson construction often involve underwater or subaqueous conditions. The tremie hopper system is used to place concrete into piles and caissons, ensuring a solid and stable foundation. This method is particularly useful in areas with high water tables or where the soil conditions require deep foundations.

Repair and Maintenance

The tremie method is also employed in the repair and maintenance of underwater structures. For example, when repairing bridge piers or seawalls, the tremie hopper allows for the precise placement of concrete to fill voids and reinforce the structure. This method ensures that the repairs are durable and capable of withstanding the harsh underwater environment.

Advancements in Tremie Hopper Technology

Automation and Remote Control

Recent advancements in tremie hopper technology have focused on automation and remote control. Automated systems can precisely control the flow and placement of concrete, reducing the risk of human error and improving efficiency. Remote-controlled tremie hoppers allow operators to monitor and adjust the pouring process from a safe distance, enhancing safety and control.

High-Performance Materials

The development of high-performance materials for tremie pipes and hoppers has improved the durability and longevity of these systems. Advanced steel alloys and durable plastics can withstand the harsh conditions of underwater construction, reducing the need for frequent maintenance and replacements.

Enhanced Monitoring Systems

Modern tremie hopper systems are equipped with advanced monitoring systems that provide real-time data on the concrete flow, pressure, and placement. These systems allow operators to make informed decisions and adjustments during the pouring process, ensuring the quality and consistency of the concrete pour.

Challenges and Solutions in Tremie Hopper Use

Segregation and Contamination

One of the primary challenges in using tremie hoppers is the risk of concrete segregation and contamination. Segregation occurs when the concrete mix separates, leading to an uneven pour and compromised structural integrity. Contamination happens when water enters the tremie pipe, mixing with the concrete and affecting its quality. Solutions to these challenges include using anti-washout admixtures, maintaining a consistent pour rate, and ensuring the tremie pipe remains submerged in the concrete.

Equipment Handling and Maintenance

Handling and maintaining the tremie hopper system can be challenging due to its size and the harsh conditions of underwater construction. Regular inspections and maintenance of the tremie pipes, valves, and hoppers are essential to ensure their functionality and longevity. Proper training and safety protocols for operators are also crucial to prevent accidents and equipment damage.

Environmental Concerns

Underwater construction using the tremie method can have environmental impacts, such as water pollution and habitat disruption. To mitigate these concerns, environmentally friendly concrete mixes and additives can be used. Additionally, careful planning and execution of the pouring process can minimize the environmental footprint of the construction project.

Case Studies: Successful Use of Tremie Hoppers

Hong Kong-Zhuhai-Macao Bridge

The construction of the Hong Kong-Zhuhai-Macao Bridge, one of the longest sea-crossing bridges in the world, involved extensive use of the tremie method.

The bridge’s underwater foundations required precise and uncontaminated concrete placement to ensure stability and durability. The tremie hopper system allowed for the efficient and controlled pouring of concrete, contributing to the project’s success.

Venice MOSE Project

The MOSE project in Venice, Italy, aimed to protect the city from flooding by constructing a series of movable barriers. The underwater foundations of these barriers required high-quality concrete placement, which was achieved using the tremie hopper system. The controlled flow and placement of concrete ensured the barriers’ stability and effectiveness in preventing floods.

Offshore Wind Farms

The construction of offshore wind farms involves placing concrete foundations on the seabed to support wind turbines. The tremie method is commonly used in these projects to ensure the precise and uncontaminated placement of concrete. Successful implementation of the tremie hopper system has contributed to the stability and longevity of offshore wind farm structures.

Conclusion

The tremie hopper is an indispensable tool in the construction industry, particularly for underwater and subaqueous projects. Its ability to deliver controlled, high-quality concrete placement is crucial for the stability and durability of various structures, from bridges and piers to offshore wind farms. Advances in technology, materials, and monitoring systems have further enhanced the efficiency and effectiveness of the tremie hopper system. Despite the challenges, the continued development and refinement of this method ensure its relevance and importance in modern construction. The successful application of the tremie hopper in high-profile projects around the world underscores its significance and potential for future infrastructure developments.