The Science Behind Heat Seal Adhesives in Food Packaging

Heat seal adhesives have transformed food packaging, ensuring that food remains fresh and safe from contamination. Understanding their application and benefits can enhance your knowledge of modern packaging technologies.

Adhesives play a vital role in the food packaging industry, ensuring that products are securely contained and protected from external elements. One of the most crucial forms of adhesives used today is heat seal adhesives, which are integral to maintaining package integrity and safety. These specialized adhesives are designed to create airtight seals when heated, making them indispensable in various packaging applications. For those interested in the manufacturing and supply of commercial and industrial adhesives, you can get more information from Technical Adhesives Limited, which provides detailed insights into their adhesive products and the industries they serve.

Heat Seal Adhesives Explained

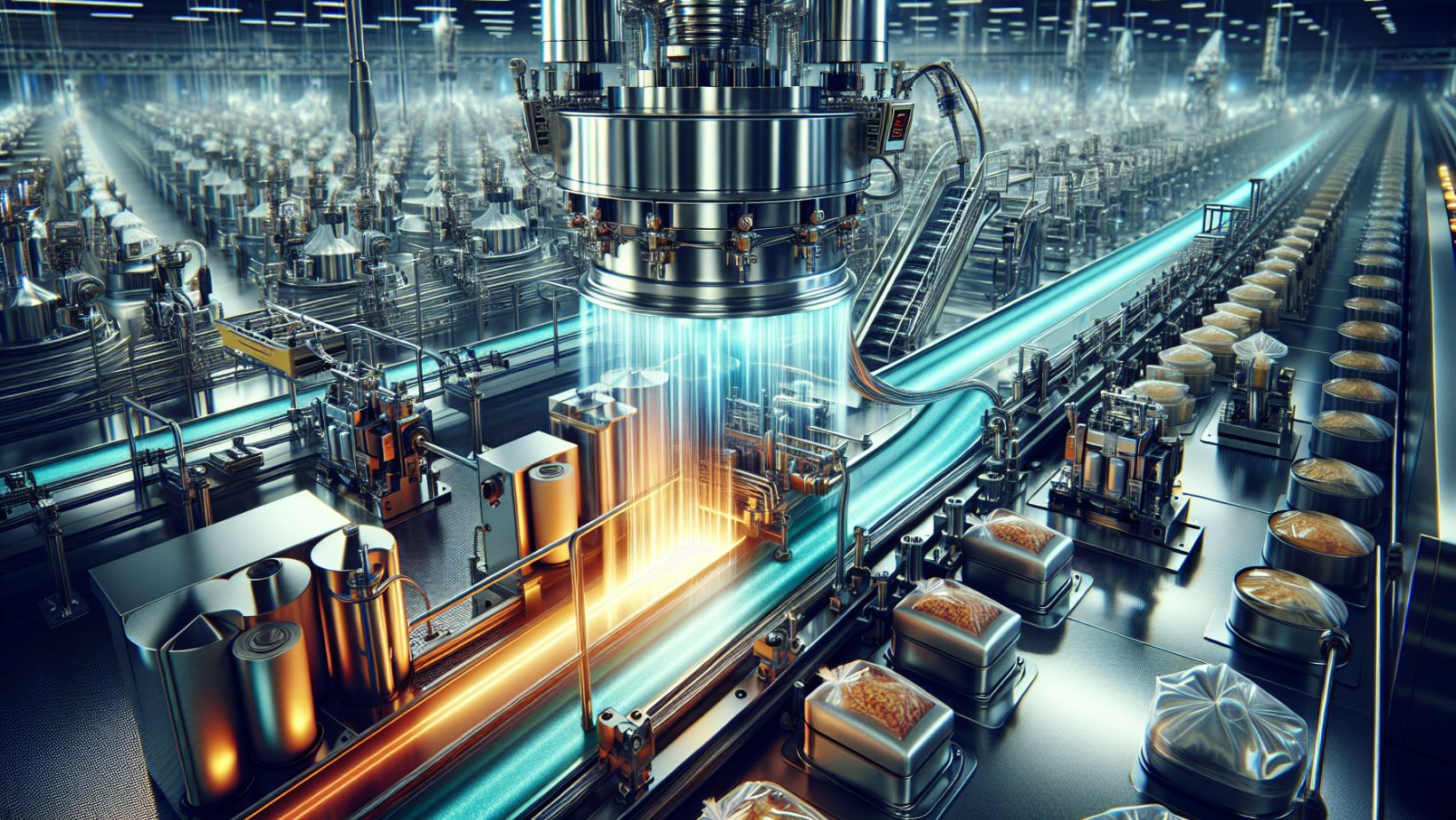

Heat seal adhesives are compounds that bond two materials together through the application of heat and pressure. Typically composed of polymers, these adhesives become tacky when heated, allowing them to form strong seals between surfaces like plastic films or foils. The process involves heating the adhesive until it reaches a molten state, then applying pressure to bond the materials securely.

The mechanism by which heat seal adhesives operate is straightforward yet highly effective. As heat is applied, the adhesive softens, flows into surface irregularities of the materials being joined, and solidifies upon cooling. This results in a robust and durable bond capable of withstanding various environmental conditions.

Applications in Food Packaging

Various types of food packaging utilize heat seal adhesives due to their reliability and efficiency. From flexible pouches for snacks to rigid containers for ready meals, these adhesives are vital for ensuring product safety and longevity. They are also commonly used in sealing lids on yogurt cups and other dairy products, providing a tamper-evident barrier that assures consumers of product integrity.

The versatility of heat seal adhesives means they can be adapted to suit numerous packaging requirements. Their ability to provide airtight seals makes them ideal for products that need to maintain freshness over extended periods. By offering enhanced protection against moisture and contaminants, they play a key role in preserving the quality of packaged foods.

Benefits of Heat Seal Adhesives

The advantages of using heat seal adhesives in food packaging are extensive. One primary benefit is the extension of shelf life, as these adhesives help keep products fresh by preventing air and moisture ingress. Additionally, they contribute to improved product safety by creating tamper-evident seals that protect against contamination during transportation and storage.

In terms of environmental impact, recent advancements have focused on developing more sustainable adhesive solutions. These innovations aim to reduce waste and improve recyclability without compromising performance. For manufacturers looking to enhance efficiency while minimizing environmental footprints, exploring new adhesive technologies can offer significant benefits.

Challenges and Considerations

Despite their many advantages, selecting the right heat seal adhesive for specific applications can pose challenges. Material compatibility is crucial; not all adhesives work equally well with every substrate type. Factors such as temperature resistance, seal strength, and regulatory compliance must be considered during adhesive selection processes.

Manufacturers must also address considerations related to equipment compatibility and application techniques to optimize bonding outcomes. Understanding the specific requirements of each application ensures that the chosen adhesive provides optimal performance without compromising product quality or safety.

Recent Developments and Innovations

The field of heat seal adhesives continues to evolve with ongoing research driving technological advancements. Recent innovations have focused on enhancing adhesive properties such as flexibility, adhesion strength, and resistance to extreme temperatures. Such developments not only improve packaging performance but also open new possibilities for innovative applications across diverse industries.

Notable research efforts have led to breakthroughs in creating adhesives tailored for specific environmental conditions or novel materials like biodegradable films. These advancements reflect a commitment to sustainability while meeting consumer demands for safer and more efficient packaging solutions.